CIM & Robotics Laboratory

Computer Integrated Manufacturing and Robotics laboratory at School of Mechanical Engineering was established to provide knowledge and hands-on experience in the area of CIM and Robotics to both the undergraduate as well as postgraduate level students in the area of manufacturing segment in the industrial fraternity. The objective of the CIM laboratory is to prepare the students’ to be industry ready and to acquire employability skills. Main purpose of this lab is to make them understand and interpret different controllers used in the industries, NC, CNC, and DNC systems, ASRS, AGV, VIS, Material handling equipment such as 6 Axis Robot, loading /unloading arm and a conveyor with the entire CIM System. Also, it is aimed to demonstrate and understand the importance of automation and its predominant role in the assembly line of the shop floor, the operating principles of hydraulics, pneumatics, and electro-pneumatic systems, Applying these learnings to automate & improve the efficiency of the manufacturing process.

Digital Manufacturing Simulation Lab is also a part of the lab wherein NX CAM, CATIA/DELMIA Software Package, Real NC, Espirit CAM, Automation Studio Workspace Robot Simulation and VR CIM Software are applied for manufacturing systems simulation. This Lab provides in-depth coverage of Automation, Computer Integrated Manufacturing, and Robotics.

Faculty In-charge: |

Dr. P. Chandrasekhar |

Co-Faculty In-charge: |

Dr. B. Surekha |

Technical Asst. In-charge: |

Mr. S. Parida |

- Automatic Storage and Retrieval System (ASRS)

- Automate Guided Vehicle (AGV)

- CNC Lathe (MTAB)

- Loading and Unloading Arm

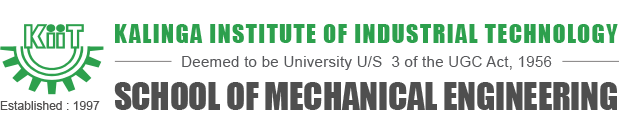

- Aristo 6-axis Robot (MTAB) 2No’s.

- CNC Mill (MTAB)

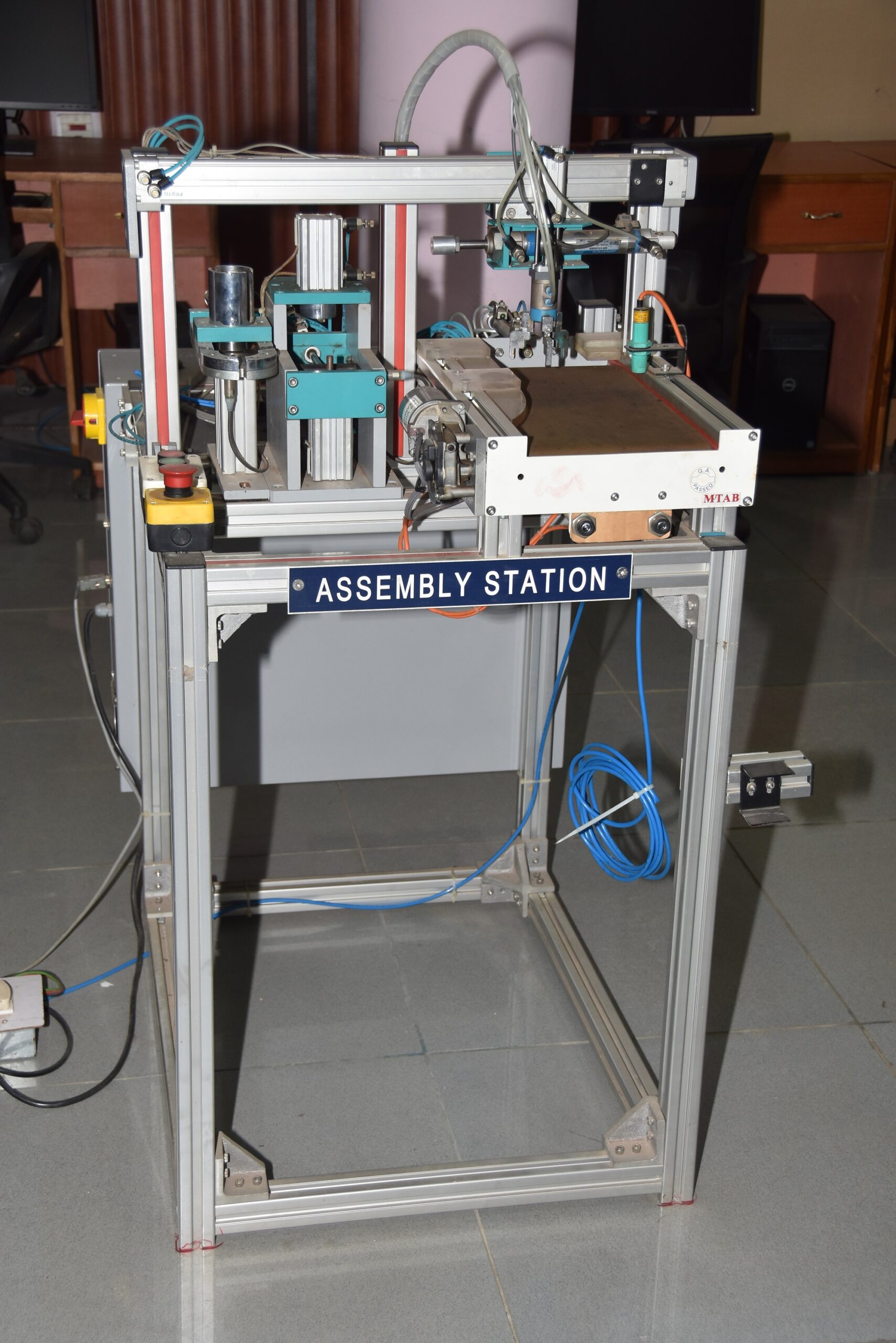

- Assembly Station

- Vision Inspection System

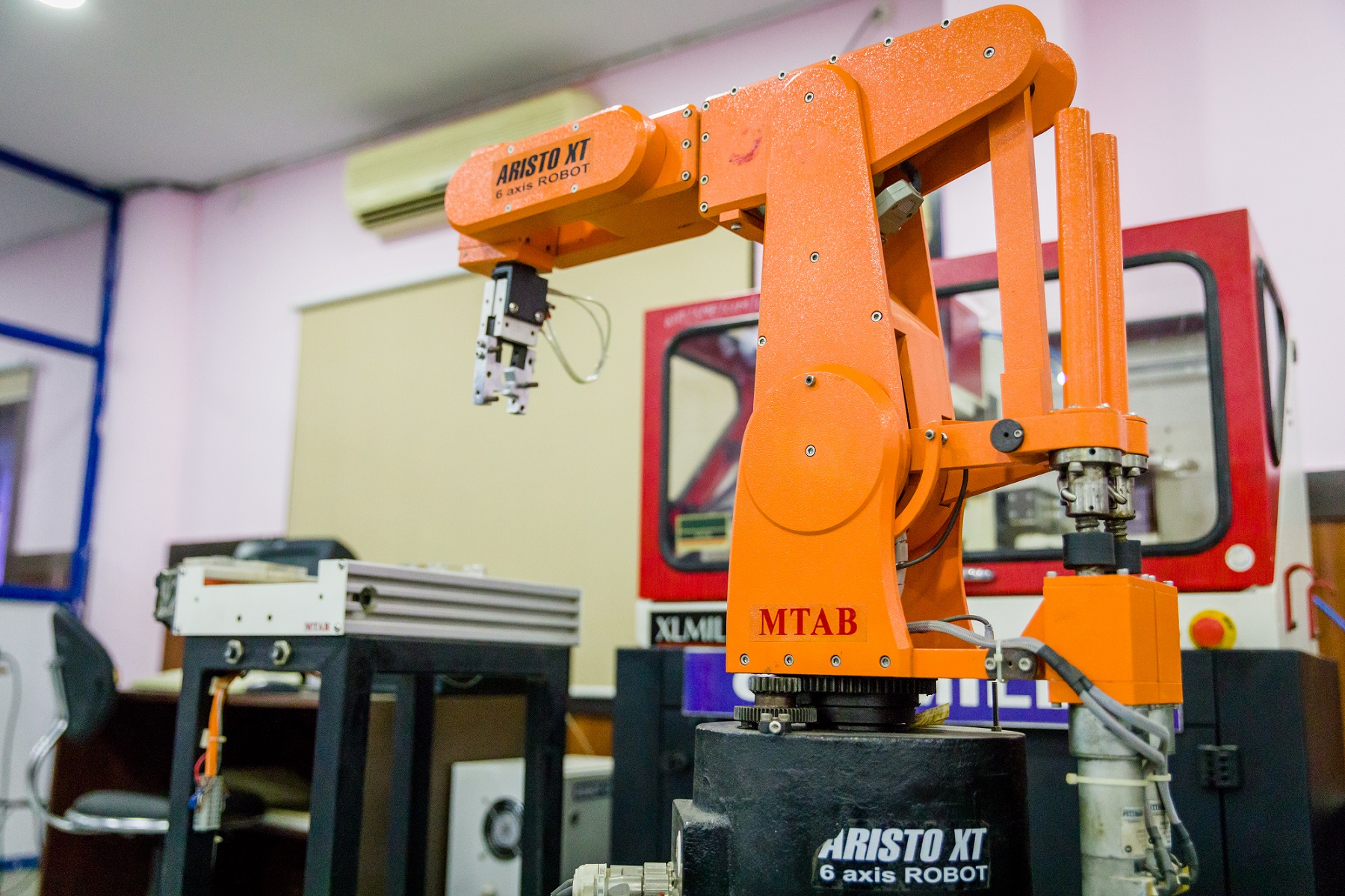

- Pneumatic KIT

- Hydraulic KIT

- Pneumatic Compressor

- Automation Studio

- Workspace Robot Simulation Software

- Espirit CAM (DP Technology)

- CNC TRAIN (Fanuc OT and Fanuc OM)

- VRCIM